Choosing the right packaging format for fruits and vegetables is crucial for maintaining freshness, preventing damage, and enhancing shelf appeal. Different formats offer unique benefits based on the product type, storage requirements, and distribution needs.

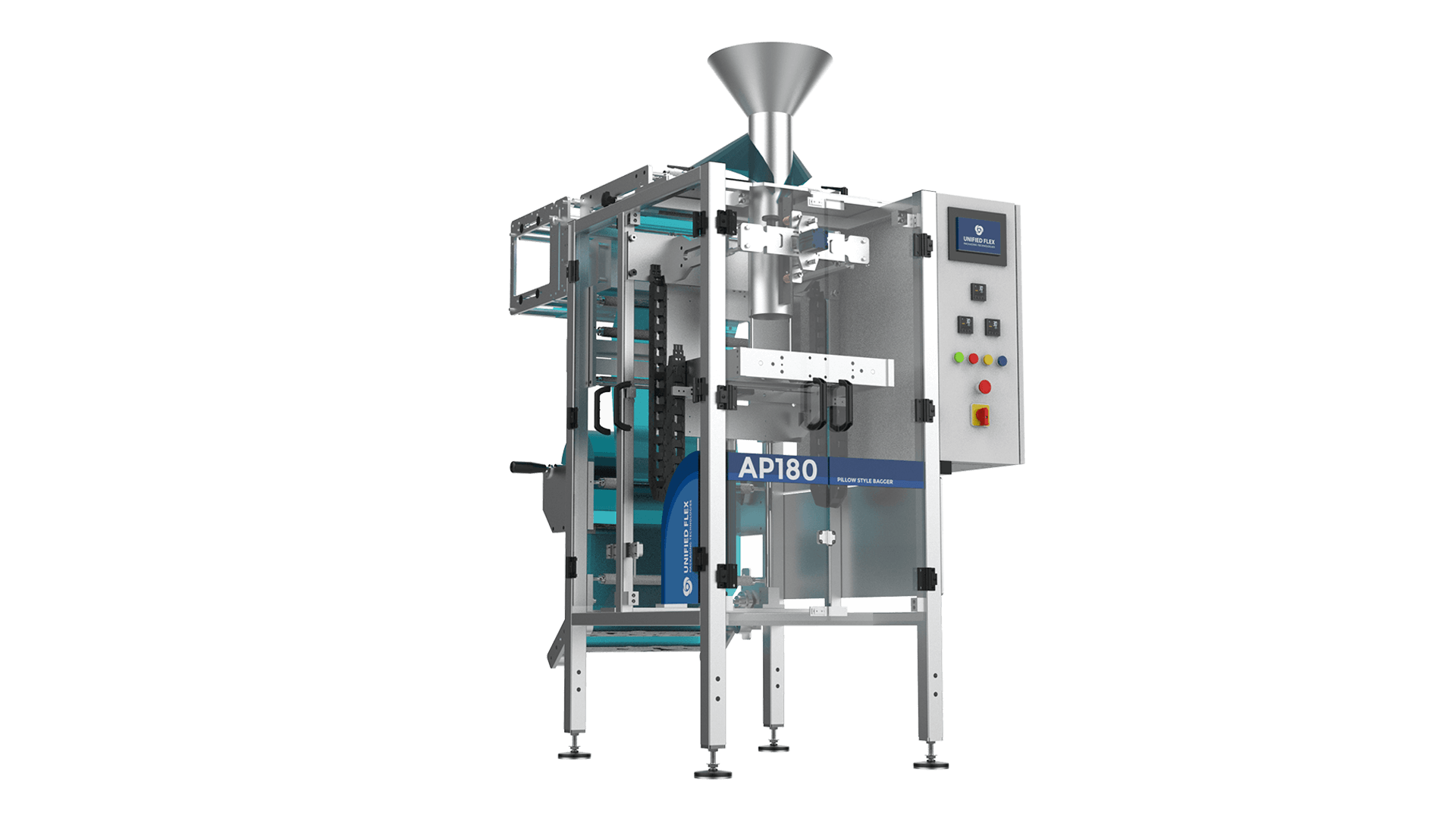

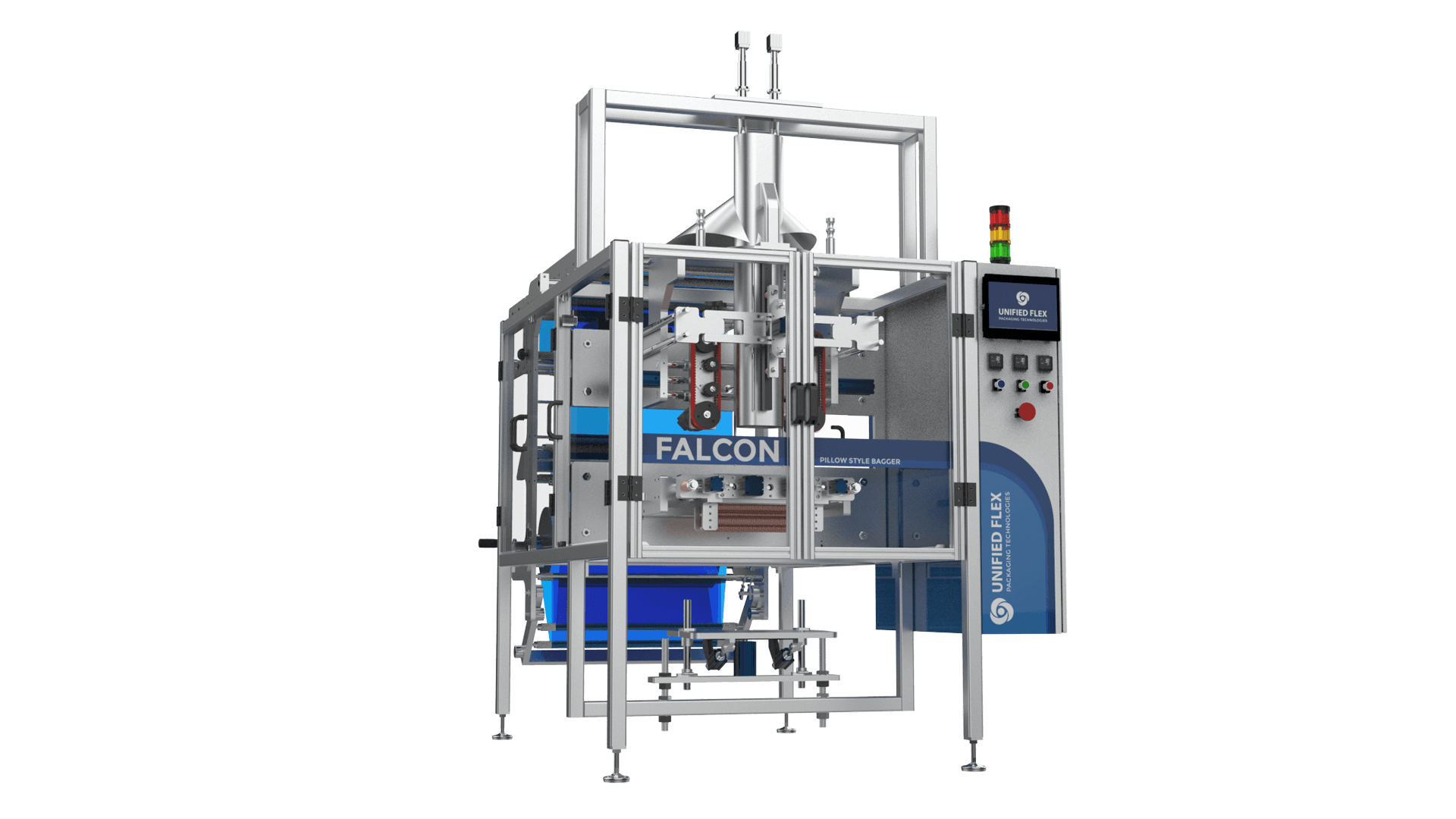

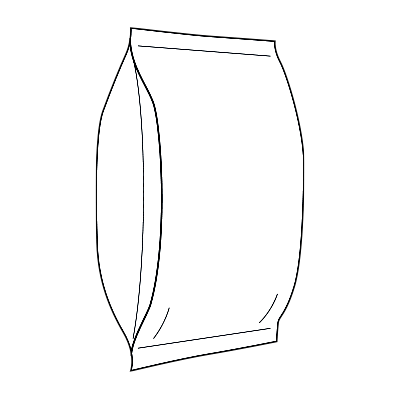

Pillow Bags: A cost-effective, lightweight option for bulk produce like carrots, potatoes, and apples. Compatible with high-speed VFFS machines and eco-friendly materials.

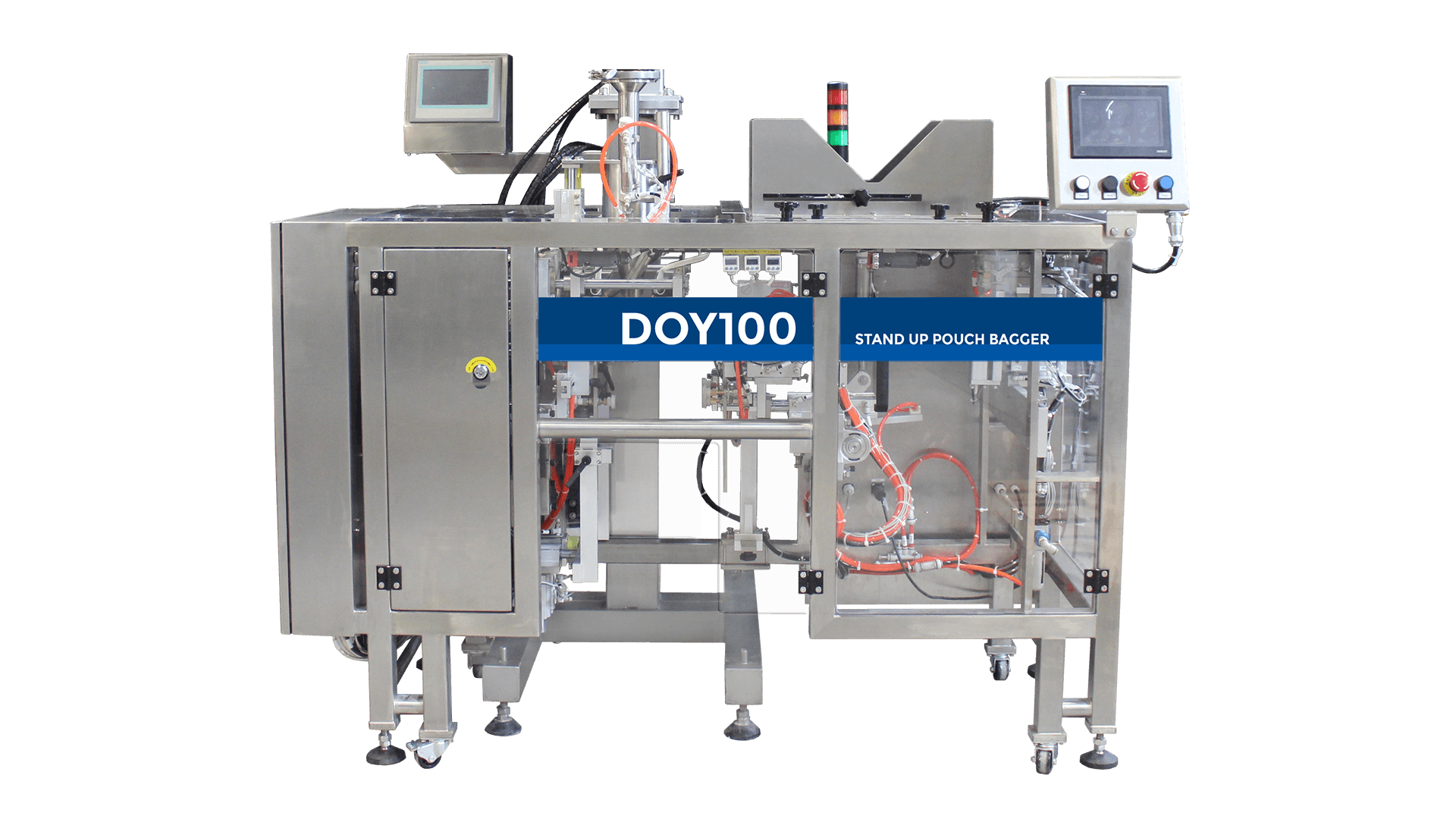

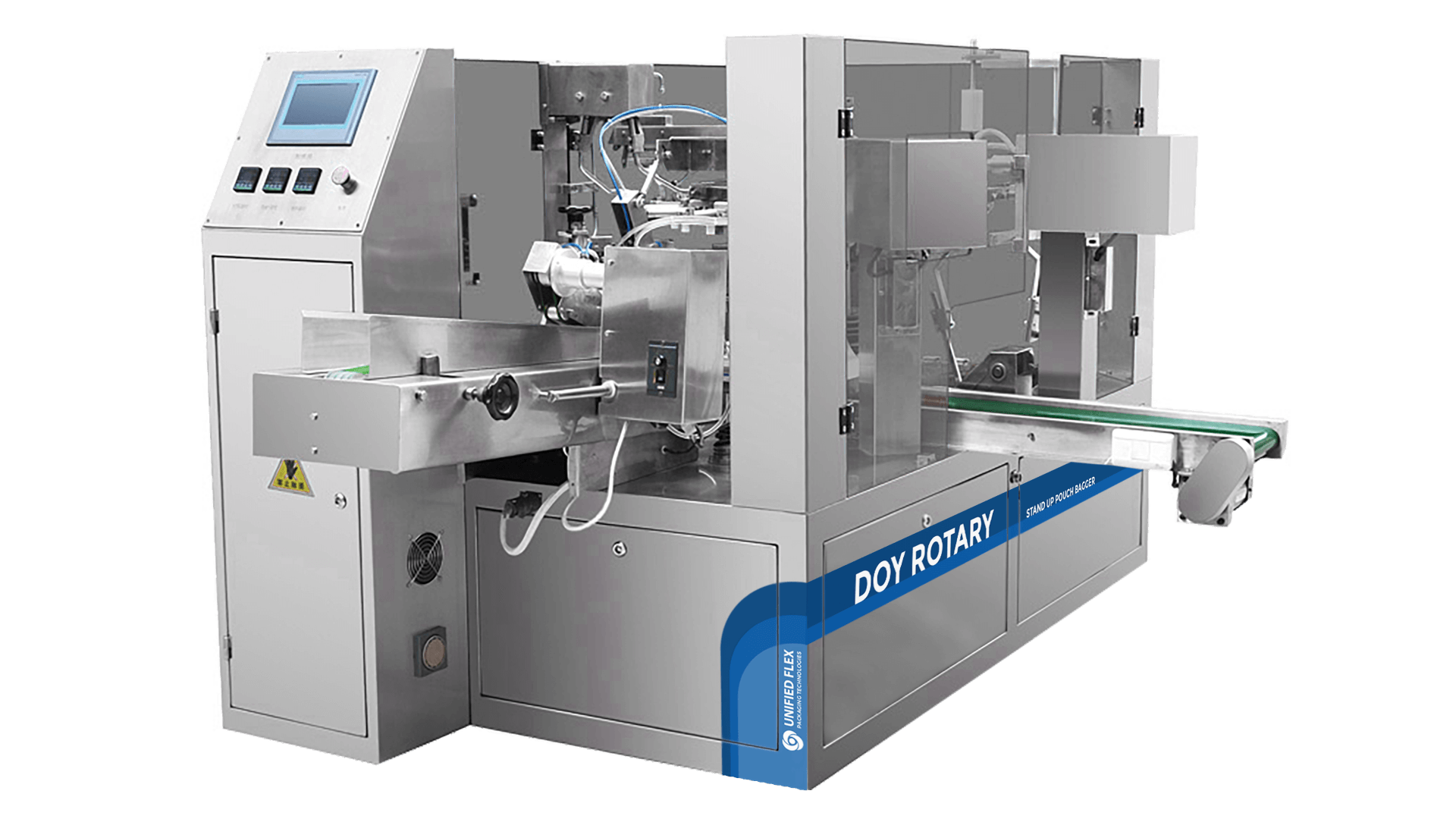

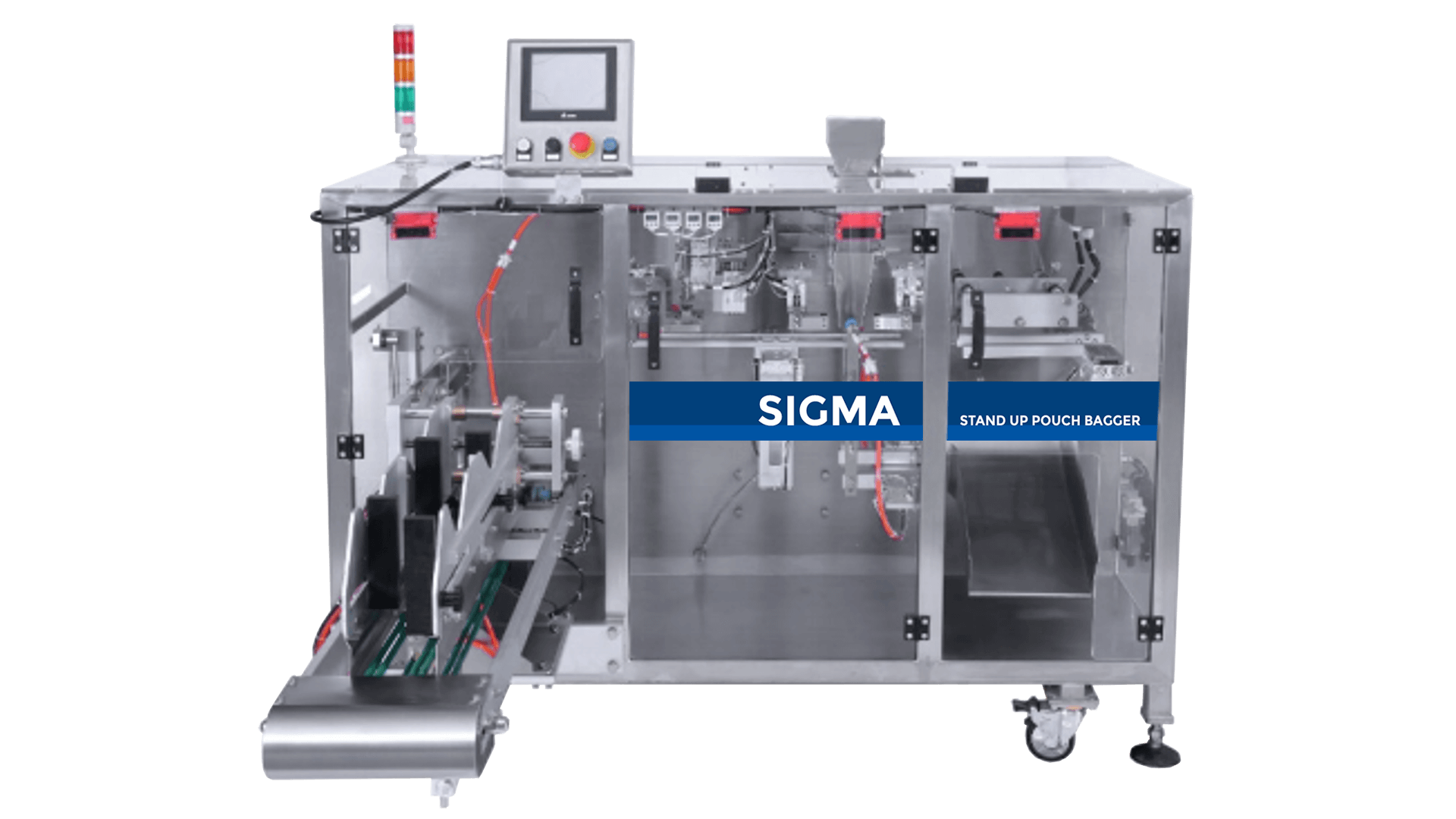

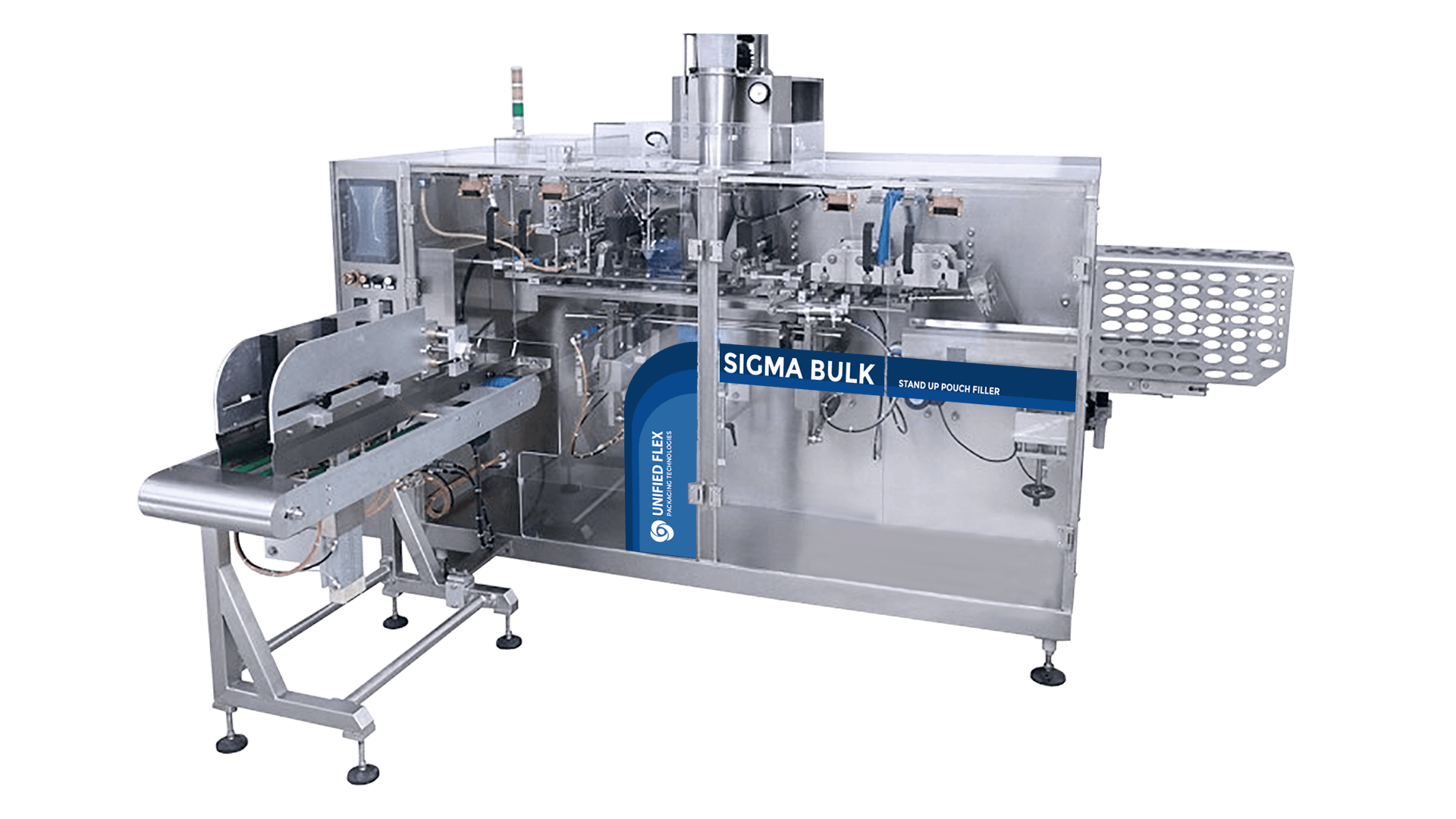

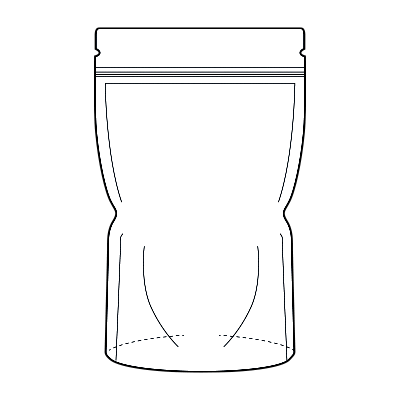

Stand-Up Pouches: Ideal for fresh-cut fruits, dried fruits, and salads. Resealable zippers maintain freshness, while strong branding and barrier options extend shelf life.

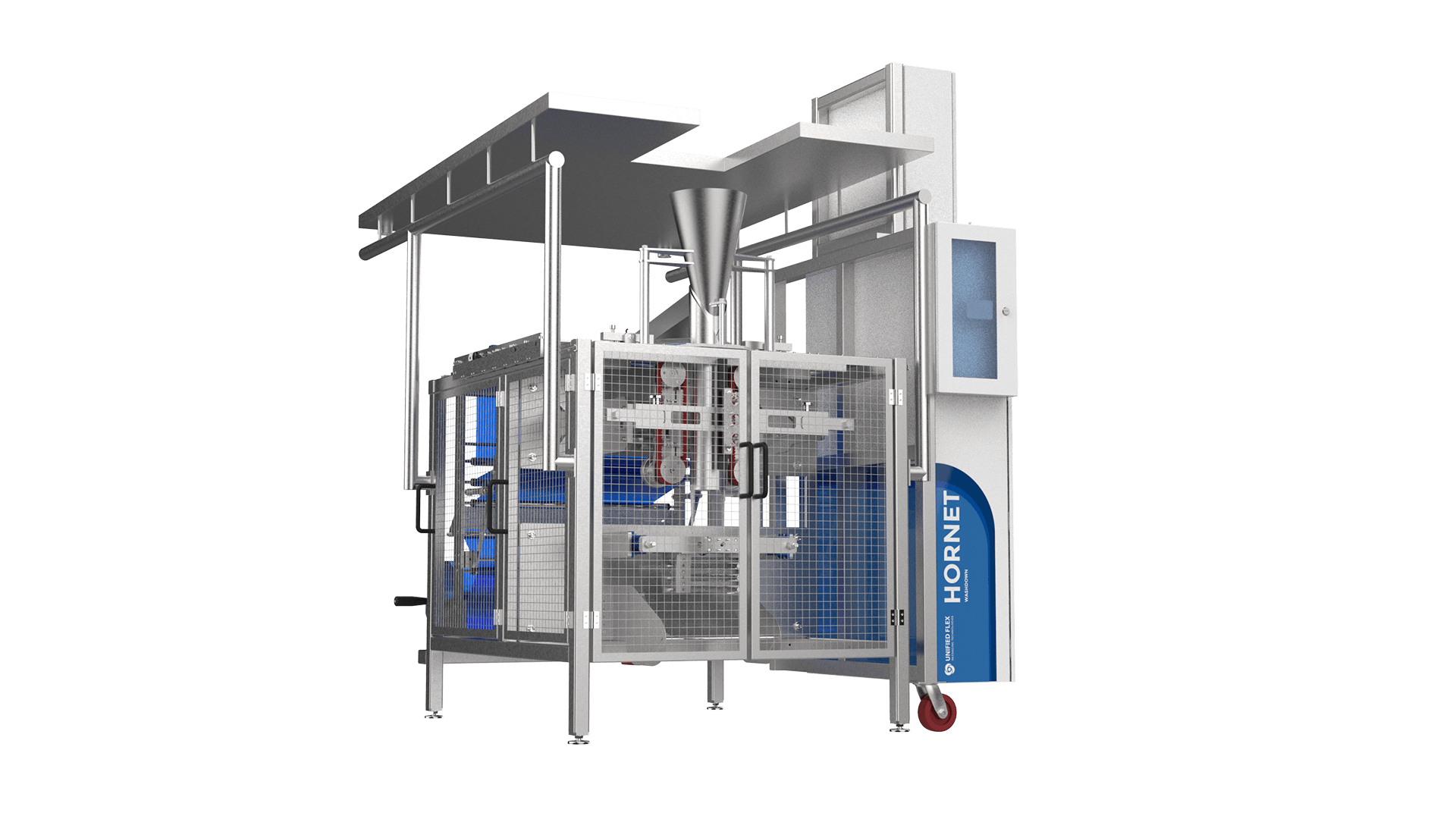

Pillow Bags with Side Gusset: Expands when filled, maximizing capacity while staying compact. Suitable for leafy greens, dried fruits, and bagged salads, with optional vent holes for moisture control.

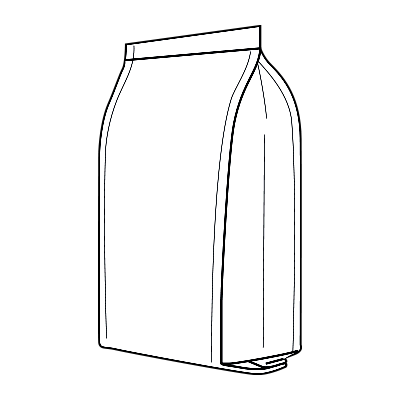

Block Bottom Bags: Premium packaging for high-end or organic produce. Stands upright for better visibility and can include resealable zippers and transparent windows.

Whether you need cost-effective bulk packaging, premium stand-up pouches, or hygienic washdown solutions, Unified Flex offers a wide range of packaging machines to meet your needs.

Call us today at 1-866-369-4181 to explore the best packaging formats for your fruits and vegetables!